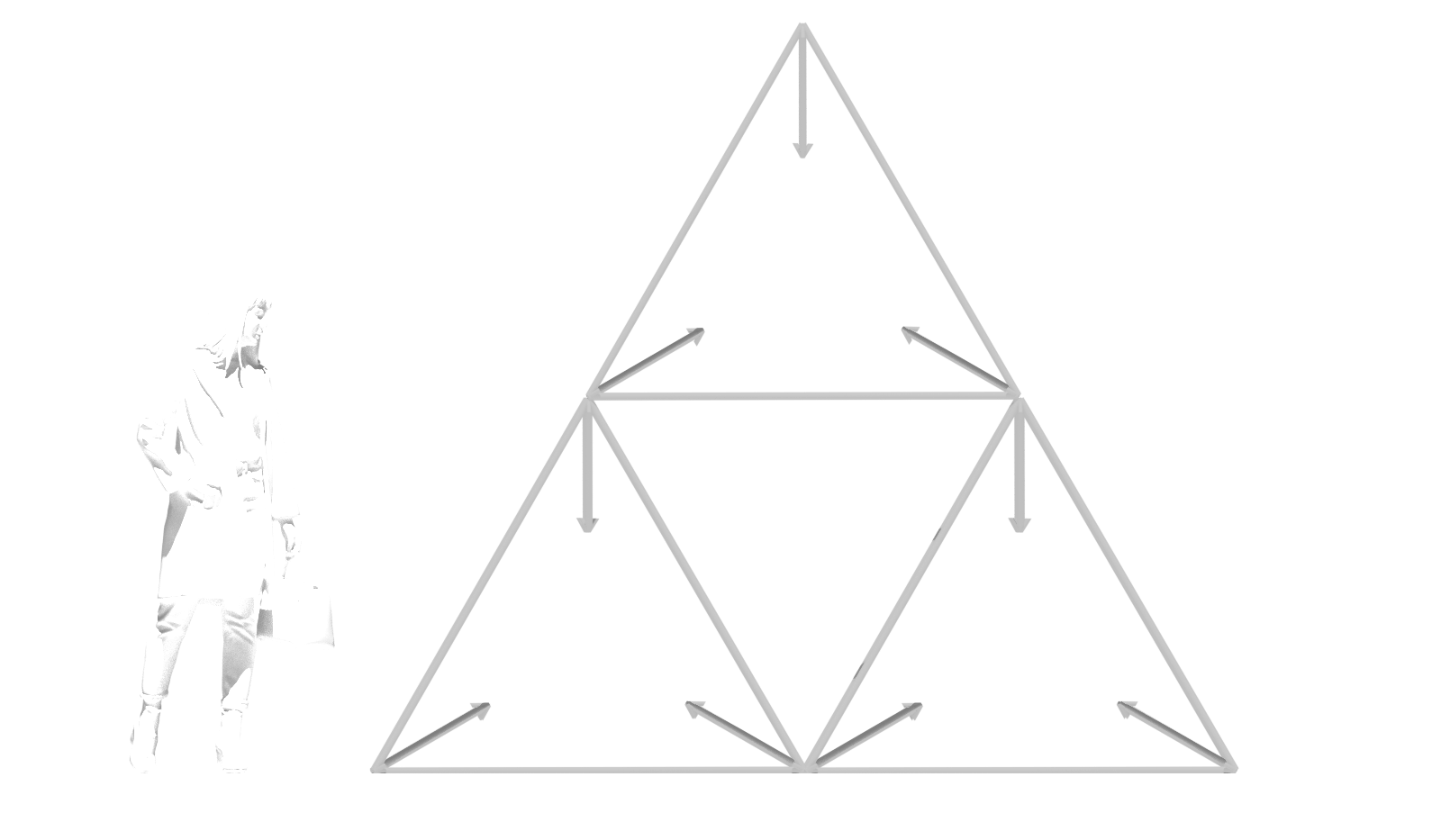

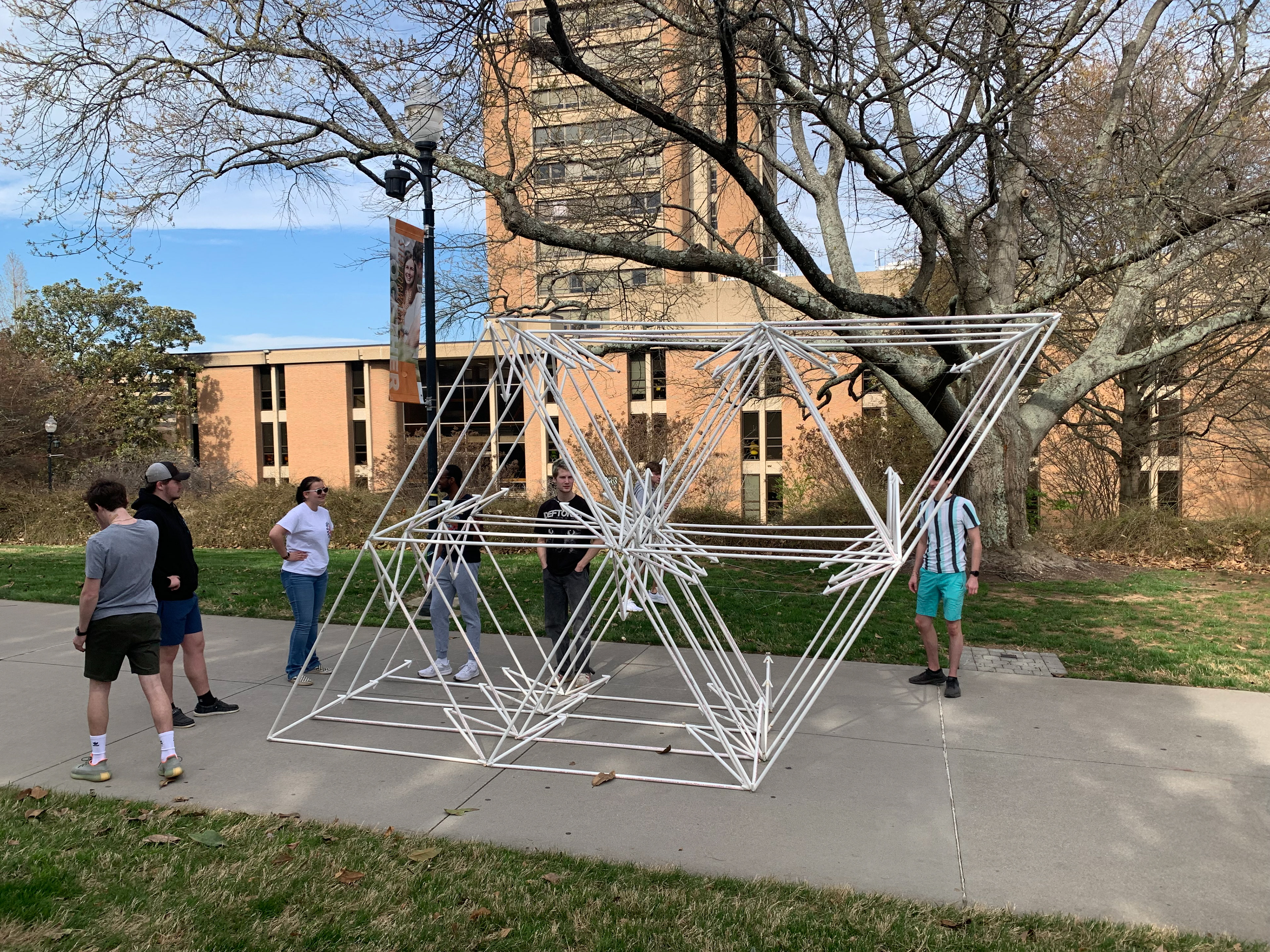

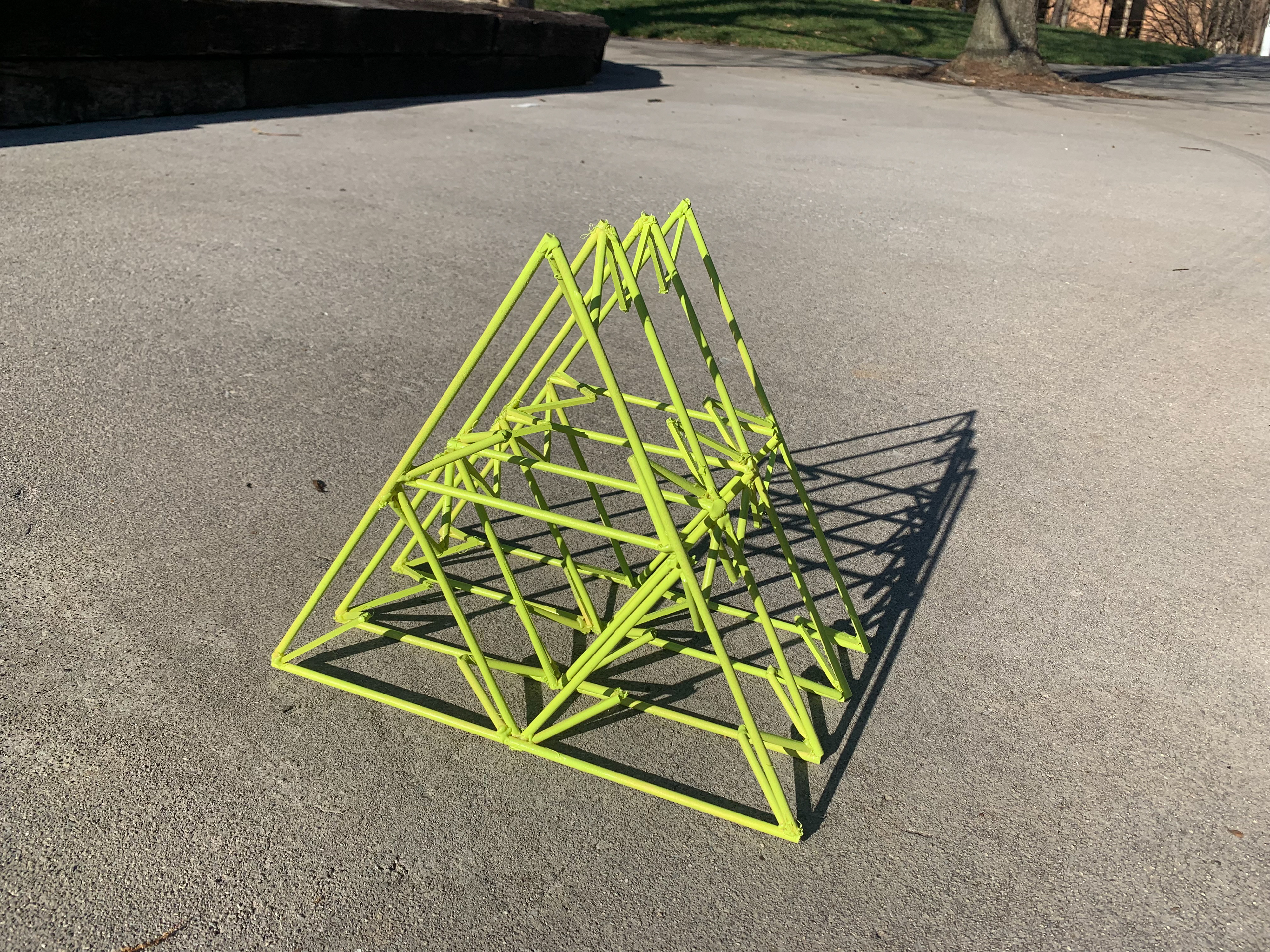

In groups of about five people, we were tasked to create a lightweight, freestanding structure using wire, forty feet of PVC piping, and a joint we designed. As the head of my team, I wanted us to create something easy to replicate and had an interesting form as a freestanding component and when joined with other components to form a larger structure. Through several iterations, we came up with the double triangle form because it used one style of joint throughout and could be connected easily with duplicates to form other shapes. Every team presented their proposal of their structure and my team was ultimately chosen because our model had the most structural integrity. I was then tasked with leading a group of 35+ students in replicating the model by heading the process of 3-D printing joints, devising a wiring system to go through the structure, and making decisions on all the complications with building a structure at this large scale. This project was a look into the real-life complications that come with building free-standing structures with strict deadlines needing to be met. My team and I learned what it is like to lead a large group in a project that had stakes of needing to be successful both as a concept and in construction.